PROJECT

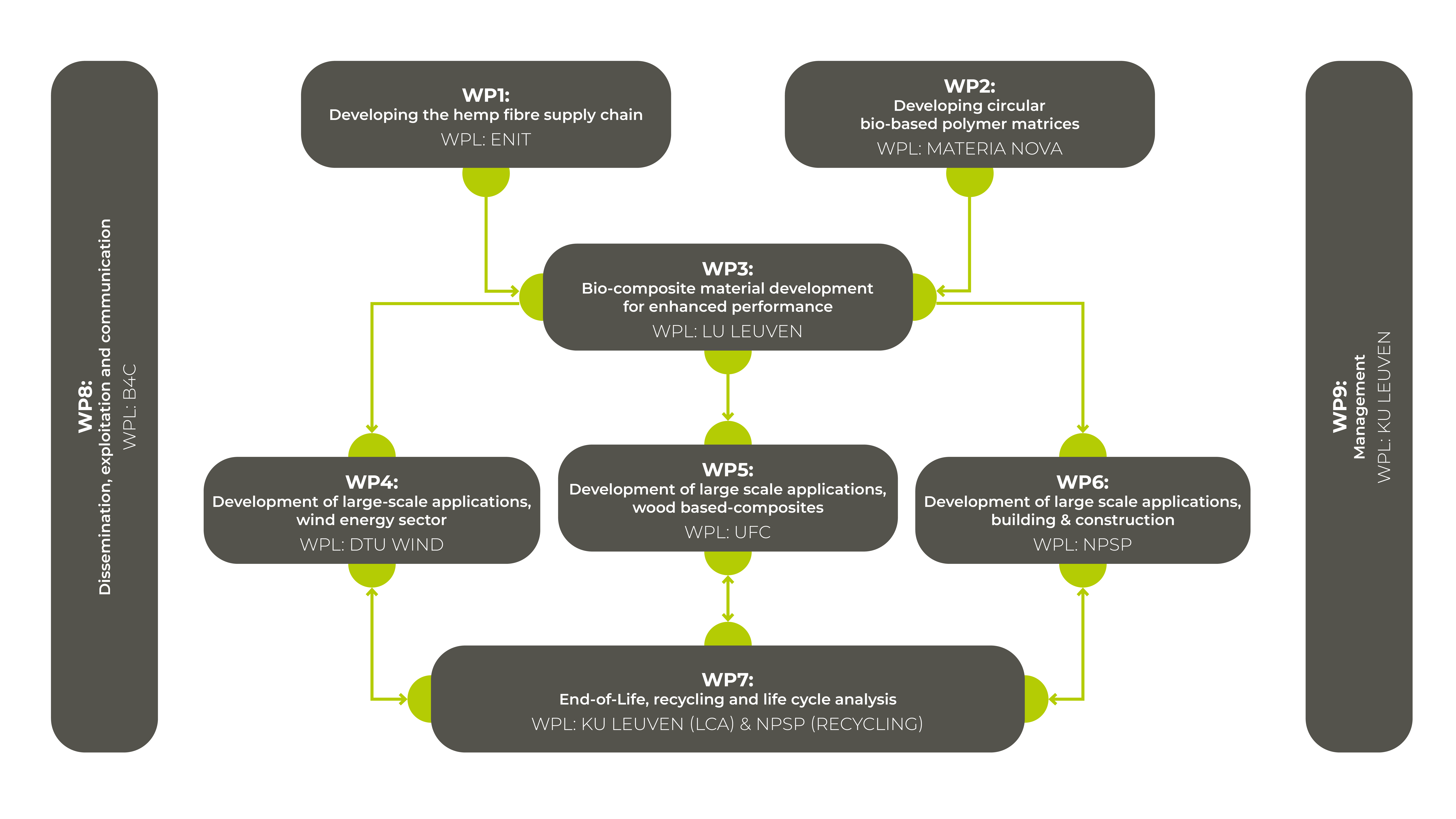

SSUCHY-Next uses a robust work chain to produce high-performance bio-based composites by integrating hemp fibre with 3 innovative bio-based resins, and demonstrates their use in industrial applications like wind turbine blades, load-bearing structural elements, bulk mould compounded products like façade panels, etc. The project includes LCAs to assess the environmental performance of these bio-based materials and a strong focus on the management of their end-of-life to ensure circularity.

- Developing the hemp fibre supply chain to produce fibre with high mechanical potential, across regions with diverse climates.

- Advancing the development of bio-based and circular matrices, focusing on bio-based thermoset resins such as epoxy anD benzoxazine, sourced from lignocellulosic biomass, while also enhancing bio-based thermoplastic resin Elium® for increased

sustainability and recyclability. - Evaluating and improving the developed hemp fibre preforms and bio-resins at the composites level. This includes enhancing

the moisture resistance, durability and fibre-matrix compatibility. - Optimising structural damping, understanding non-linear material behaviour of the bio-composites for various applications.

This include enhancing the fire, smoke and toxicity performance. - Producing 95% bio-based composite materials and aiming for at least 90% bio-based resin.

This includes creating a 12.6m long bio-based wind turbine blade, optimising manufacturing processes, and comparing performance

and carbon footprint with traditional counterparts. - Developing wood-based composites to replace glass-based materials and metal in the automotive and construction sectors.

- Demonstrating large-scale building and construction applications of circular bio-based composites, optimising manufacturing

processes and reducing the environmental footprint. - Proving improved life cycle assessment (LCA) and circularity of bio-composites, supported by demonstrated recycling options,

employing prospective LCA for future scenarios and setting up recycling technologies without damaging natural fibre reinforcement.

- Developing the hemp fibre supply chain to produce fibre with high mechanical potential, across regions with diverse climates.

- Advancing the development of bio-based and circular matrices, focusing on bio-based thermoset resins such as epoxy anD benzoxazine, sourced from lignocellulosic biomass, while also enhancing bio-based thermoplastic resin Elium® for increased sustainability and recyclability.

- Evaluating and improving the developed hemp fibre preforms and bio-resins at the composites level. This includes enhancing the moisture resistance, durability and fibre-matrix compatibility.

- Optimising structural damping, understanding non-linear material behaviour of the bio-composites for various applications.This include enhancing the fire, smoke and toxicity performance.

- Producing 95% bio-based composite materials and aiming for at least 90% bio-based resin. This includes creating a 12.6m long bio-based wind turbine blade, optimising manufacturing processes, and comparing performance and carbon footprint with traditional counterparts.

- Developing wood-based composites to replace glass-based materials and metal in the automotive and construction sectors.

- Demonstrating large-scale building and construction applications of circular bio-based composites, optimising manufacturing processes and reducing the environmental footprint.

- Proving improved life cycle assessment (LCA) and circularity of bio-composites, supported by demonstrated recycling options, employing prospective LCA for future scenarios and setting up recycling technologies without damaging natural fibre reinforcement.

expected impact

The expected impacts of SSUCHY-Next are in line with the CBE-JU roadmap: the SIRA. SSUCHY-Next and all its partners will actively contribute to the structuration of a sustainable bioeconomy value chain in Europe.

Reinforcing the integration of bio-based research and innovation

throughout industrial bio-based systems

5 Academic partners and 2 Research centres connected to 7 SMEs, 2 Large companies, 1 Cluster (SDG 9)

Improved life cycle environmental performance of bio-based products

7 innovative bio-based products, sustainability demonstrated by LCAs (SDG 9 &12)

Support new jobs, growth and investment

stimulation of the local and regional economy, creation of jobs in the research fields (at least 7 PhD’s) (SDG 9 &12)

Ensure environmental sustainability of the feedstock

At least 4 industrial partners positioned on the sourcing and

the production of the hemp and the bio-based resins (SDG 12)

Readiness for a market uptake of bio-based products

9 industrial partners advancing the readiness of their products

to TRL7 (SDG 9 &12)